With the advent of various technologies, the world of cabinet making has undergone significant changes recently. It has come a long way from hand tools, chisels and hours of hard manual labour to the automatic machining process.

Among the various technologies, CNC machining in Sussex has been transforming the way cabinets are designed and refinished. The cabinet makers use this technique to design, cut and assemble the cabinets with complete precision and without hours of hard labour. This helps to improve efficiency, creativity, and accuracy of the process.

Here are a few benefits of CNC in Sussex. This can help you understand how CNC machining is revolutionising the cabinet-making system.

Benefits of CNC machining in cabinet making

Highly precise and accurate finishing

One of the biggest advantages of CNC machining is its unmatched precision. In the traditional cabinet-making process, cabinetmakers used to manually measure, cut, and design the cabinets, leaving a few inconsistencies in the process. However, with the advent of CNC machining, every design, every hole, and every cut is made precisely and with pinpoint accuracy. This involves a flawless finish and also makes the cabinet assembly easier. Moreover, the cabinet makers can use this machining technique to work on larger projects and complete them within a short period.

Endless possibilities of creativity

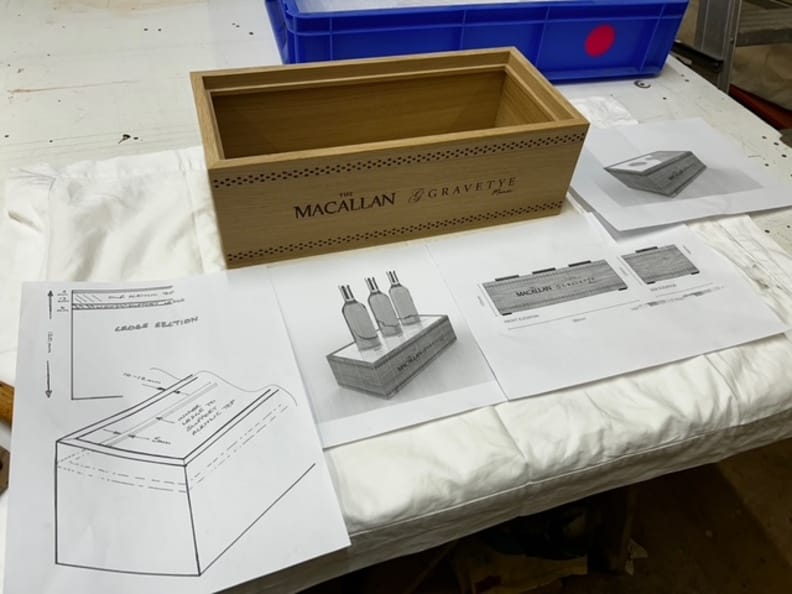

CNC machining provides cabinet makers with endless design possibilities. Whether you are looking for a curved cabinet, personalised with engraving or complex designs on its surface, it is possible with this machining technique. The machines can execute intricate patterns on the cabinet surface in a matter of seconds. This gives the makers the flexibility to showcase their creativity with the help of bespoke designs, which makes the cabinets attractive and appealing.

Consistency in all pieces

Traditional cabinet making was a hectic process where consistency in designs, shapes, and sizes of all the cabinets was not expected. However, with the help of CNC machines, every drawer, cabinet door, and side panel will look identical and have the same measurements. This consistency enables the delivery of bulk cabinets for large projects. Having consistency in the size and shape of the cabinets also improves the visual appeal of the projects.

Faster delivery time

With the traditional cabinet-making process, even a simple design required days or weeks to complete. However, with CNC machining, this process can be sped up. The machine is used for cutting panels and routing designs, which makes half of the work done without human intervention. Since CNC machines are computer-controlled, they can run continuously without brakes, resulting in faster delivery times. These machines can be used with minimal supervision, allowing the cabinet makers to take on more projects without compromising the precision and quality of the cabinets.

Cost-effective option

For small and medium cabinet shops, a one-time investment in CNC Technology is a cost-effective option, as it helps them secure more projects through increased output and top-quality cabinet production. Using CNC machining helps improve the quality of design, reduce waste, minimise errors, and increase output.

For cost-effective CNC routing for your cabinets, get in touch with Alden Cabinet Designs. We rout, shape and profile solid wood, MDF, plastic, and other materials to your specification, and our team can produce retail displays, signs, patterns, grilles, screens, wall art, fretted panels and all kinds of components.